A viewpoint by June Sum, Consultant.

Quality is one of the most important management principles for any organization regardless of industry. This is particularly true for the pharmaceutical sector: maintaining quality product standards is essential for the prevention and treatment of numerous medical disorders.

Although the pharmaceutical industry has been around for centuries, in recent years we have experienced an increase in the number of drugs being launched in the market. As a result of this increase, the need for quality assurance and quality control measures has risen. For instance, drug manufacturers must follow strict guidelines to get their drugs approved by the FDA (Food and Drug Administration) in the United States. Such guidelines include requirements for testing, manufacturing, labelling, packaging, storing and distributing pharmaceuticals.

Quality Management

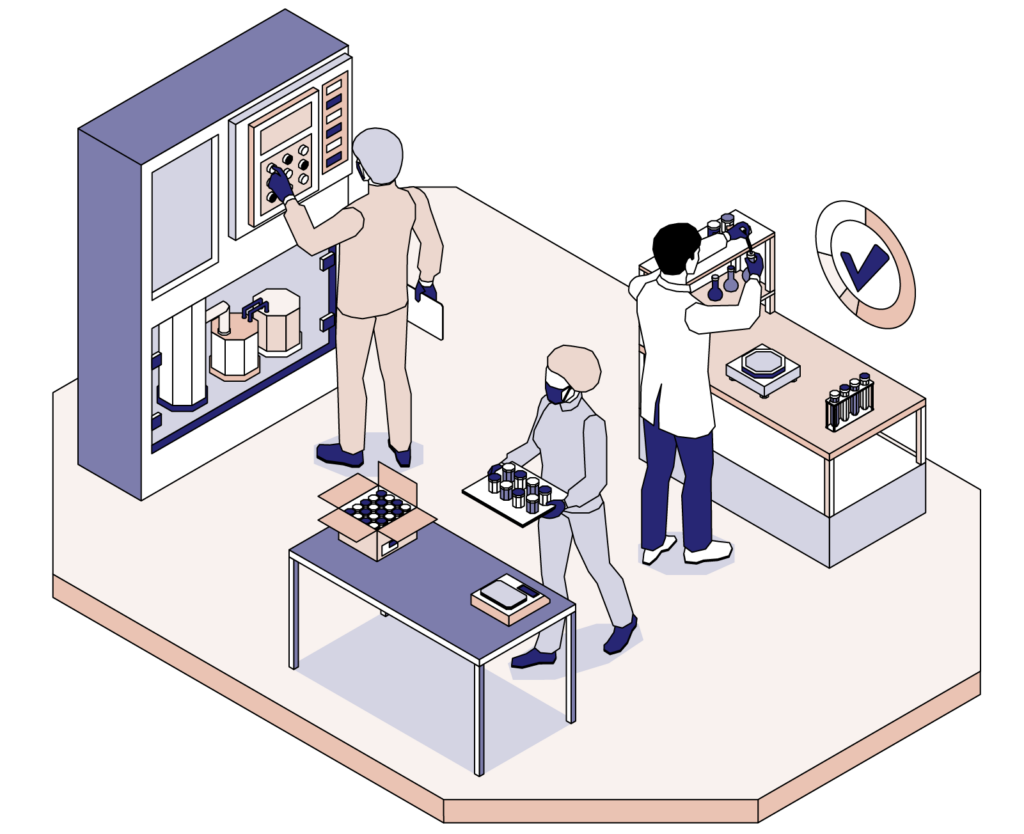

Good Manufacturing Practice (GMP) is the element of quality management that ensures goods are produced and controlled according to the quality standards of their intended use and that they meet the requirements specified by the marketing authorization or product specification. Additionally, it ensures that manufactured goods are safe, of high quality, and effective. For pharmaceutical companies, GMP entails the monitoring of procedures, apparatuses, employees, and environments.

Quality planning, quality control, and quality assurance are all important aspects of quality management too. We’ll look at what quality management is, why it’s important, and the main components and principles of quality management in this article.

Quality planning

Quality planning refers to the process of defining the quality requirements and standards of a product or service and identifying the resources needed to meet such requirements and standards. The planning phase is the first stage in establishing a good quality management system. It is in this phase that companies define their baseline quality objectives. Once goals have been set, organizations must determine what is required to achieve these objectives and what procedures should be implemented to ensure their success. During this stage of the quality management process, it is important to keep in mind the following considerations:

- The organization’s definition of success

- How often procedures and processes will be evaluated for improvement

- If the stakeholders have any quality-related priorities, goals, or ambitions

- If there are any legal procedures or standards that must be followed in order to achieve the desired quality level

Quality Control

The data collected should be presented in a way that makes it simple to examine. Document management software enables teams to create and easily share histograms, run charts and cause-and-effect diagrams.

Quality control involves ensuring standards and procedures are being met. This may include conformance testing as well as feeding information back into the initial system and examination phases. It is important to apply quality management throughout the entire manufacturing process.

Quality Assurance

Quality Assurance (QA) is a broad concept that encompasses all factors that could potentially affect the quality of prescribed pharmaceutical products. The goal of quality assurance is to verify that prescribed medications provide the desired effect to its consumers; safeguarding patients from receiving defective or contaminated prescriptions by accident; and ensuring that medications comply with regulations.

Pharmaceutical Quality Systems (PQS) consist of eight pillars that help companies oversee quality management methods with ease: allowing the consistent delivery of pharmaceutical products of the highest quality.

The eight pillars of PQS:

- Quality risk management

- Auditing

- Quality management system consultancy & design

- Good distribution practice & good manufacturing practice compliance

- Training

- Standard operating procedures development

- Qualified person & responsible person provision

- Inspection preparation & support

Quality Improvement

Once the quality management process is complete, reviewing the results and developing an action plan for improvement is key. Continuously performing the quality control management process, re-evaluating both the procedure and the product while keeping compliance in mind, will result in a better final product, happier customers and more profit.

At Amaris Consulting, we offer a wide spectrum of services to pharmaceutical, medical device, and biotechnology companies. Our quality experts assist businesses in meeting and exceeding customer expectations while supporting you throughout the entire drug development life cycle.